I am excited to report that we’ve made significant progress on our HVAC upgrade project! A while back, I shared an article when I first fully realized how it’s important to have a plan for major home equipment replacement, largely because these decisions have significant potential impact and we don’t make them very often. In addition to higher up front costs, a rushed or suboptimal decision can be particularly costly in terms of energy, health, and comfort. The fact that the decisions are infrequent means that negative effect are extended over years, sometimes even decades. This also means that great decisions have lasting and amplified positive impacts.

In a sense, our HVAC equipment replacement plan started right when we moved into our home. Our home inspector shared that our boilers were not the most efficient even though they were “good for their time” when installed, but that they would last months or years. He didn’t know exactly when, but at some point we’d have to replace them. That was almost two decades ago, so I felt we were pushing our luck. As I became more educated green building products, services, practices, and concepts, and particularly about electrification and energy efficiency and about indoor air quality and our health, I became both excited to undertake this project and honestly anxious that I need to do it as SOON as possible!

Our Project Goals:

- Replace our existing boilers with current and reliable technology

- Reduce fossil fuel consumption and emissions, specifically natural gas

- Reduce energy consumption

- Improve indoor air quality, or IAQ

- Create a better area for our outside HVAC equipment

Our decision to keep gas for our boilers was largely impacted by the fact that we already had gas in this house and that we knew that at very cold temperatures, gas boilers can still be more efficient. I should also note that we have a gas generator to help in the event of power outages, so it’s not like we were planning to remove gas from the property entirely. And finally, I will say from a real estate investment perspective, it would be considered odd to remove gas in our area as it’s still seen as a benefit if not an expectation. So my goal became more to reduce this usage as much as possible.

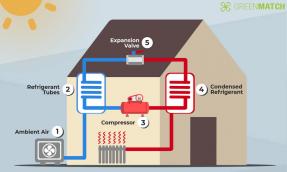

I was also super excited to reduce our overall consumption. Heat pumps are typically 300-400% more efficient than you average gas boiler. As long as electricity rates aren't particularly high, this also means saving money. An interesting fact is that if we switch to electric powered equipment, the energy efficiency impact of this decision is not likely linear in that the projected savings per year over time can grow as the grid also becomes more efficient. At the same time, environmental impacts are also further reduced.

The more I learn about indoor air quality, or IAQ, the more I am worried about health effects from irritants and pollutants we don’t even fully understand. So few of the zillions of existing chemicals are regulated, and volatile organic compounds, find dust, allergens, and other particles and pollutants are off-gassing, or leaking from products and chemicals into our indoor air space. We do not fully understand all of the potential short and long term risks from poor air, but we know some and they’re alarming. The connection between natural gas cooking and asthma alone is worth reconsidering how prizes many have considered natural gas stoves. Monitoring indoor air is just really taking off as a practice, especially as some more mainstream thermostat brands include some air quality measures in their equipment and it’s not clear that most people are prepared or able to take the steps needed to sufficiently prevent, clear or clean up many of the substances in the air that can cause us harm. In our project, I wanted to see what steps we could reasonably take to bring in sufficient fresh air and to filter out pollutants. I was and remain interested in continuing to learn what we can keep doing as well.

I had one unusual goal which is also to make the areas where our compressors are located less ugly. I know that sounds silly, but in all seriousness I had shared in the past that compressor placement is important to consider in colder climates. Our compressors were pretty close to the ground and were located near an area where our snow tends to build up due to plowing patterns and roof shape. So I had wondered what to do to protect them, and it seemed great to address this and make our overall project as comprehensive as I could.

What We’ve Accomplished to Date:

Below is a list of our completed installations and action items so far, with some limited explanations. I say so far as I remain interested in a few last steps, including continuing to learn about and work on indoor air quality.

- Installed 2 replacement 96% energy efficient gas boilers (standard today is around 90%)

- Installed 2 replacement humidifiers to replace older equipment

- Installed two VRF air sourced heat pumps

- We had conventional air conditioning prior with gas heating, and now we have a hybrid system. Above 30 degrees, the heat pumps will take over our heating from the gas boilers – We’ll also work to find the balance point, so that we may lower that threshold.

- This includes installing two ceiling cartridge units which also address comfort issues in areas where we had insufficient heating previously

- Moved one existing mini split to an alternate location in our basement where we did not have cooling capacity previously. This mini split was not compatible with our planned equipment in terms of working seamlessly as a part of one system, but we found a way to keep it!

- Installed 3 ERV’s (1 was a replacement), one in our basement and two on our second floor

- Installed a remote kitchen exhaust fan and make up air to bring fresh air into the kitchen

- Pending: We’ve planned for and have done some preparation work to install an additional heat pump for the future where we had a newer heat pump compressor which only delivers air conditioning at this time. We’ve installed the line sets and have made provision for low voltage power so that the future project to replace the compressor for this zone will be far less invasive. Basically, we’ve don't the construction part of that now!

Project Benefits

I am so excited to have made progress on so many of my key HVAC goals and to have idea on how to keep learning and to keep making improvements, particularly where IAQ is involved. Clearly we had to replace our boilers, and I wanted to get the most efficient equipment reasonably available, that could also be repaired (I didn’t want the Jaguar of boilers). But my plan was to see how much we could to do given this already existing home to increase efficiency, reduce consumption and emissions, and improve our health and comfort. We are clearly on our way!

We expect to save money from our energy reductions, and I am excited to see how the house will perform, but it’s too soon to calculate our investment returns and savings because we haven’t yet been through a full year with the new systems in place. I look forward to reporting how this all went in a couple of years when we have some numbers. Most of our new equipment is so much more energy efficient, though I know electric rates mean energy consumption per energy unit can be more expensive than with gas, and I know that ERVs increase energy consumption as they work to bring in fresh air, but we do expect our overall energy bills to be lower. The question really is how long it would take to pay back our investment, and that we do not know yet. This is all harder to model on existing homes with so many unknowns that can’t be input into a model, but we look forward to finding out over time.

Before this project, our home had two 83% efficient gas boilers from the mid 1980s and conventional A/C units which provided cooling only. We had one mini split serving a single zone in a space that had been added to our home more recently. We knew our boilers had limited life left, and they had recently stopped communicating properly with the controllers. So even if they kept working, we would have to make a significant investment in new control technology. Prior to this project start, we learned (and smelled) that we had a small gas leak. It was making me so stressed out! So the first thing we did was speed up the boiler replacement. When the old boiler pipes were removed, the areas leaking the gas went right along with them. We also had an open vented gas system before, which means there was an air gap between our boilers and exhaust pipes. It seemed likely we may also have had a post-combustion leak of some of this air as well, which was also resolved with our new closed-loop system.

Every time we use our boilers now, we’re using 13% less gas than previously. And when it’s warmer than 30 degrees, we won’t be using any gas to heat and cool our home! The one older compressor we kept uses heat pump technology. We do still have gas for cooking, but we installed a remote hood fan to reduce noise, and now everyone is much happier to use the hood. And using the hood means we’re removing pollutants that result from using gas as a cooking fuel. We also installed make up air as a retrofit, so that directed fresh air will replace the air the hood removes, which helps ensure we won’t draw this replacement air through wall cracks and crevices that might not be particularly healthy when effectively used as filters.

The remote hood is one part of our air quality and comfort improvement efforts. As long as we use the hood, I know we’re breathing better air when we’re cooking. The ERVs, or energy recovery ventilators are also a significant part of our IAQ plan. These pieces of ventilation equipment bring in fresh outside air and exchange this air for potentially polluted or even just stale inside air while also working to reduce temperature differences between the two air streams so this exchange can be as energy efficient as possible. Fresh air is important for diluting pollutants, irritants, and allergens, but it is also important to have a robust filtration system. We have a good filtration system it did not make sense to replace at this time, but this is something we may look at again in the future. I am pleased to have replaced older humidification equipment, but I admit I am paranoid about mildew and mold risk, so I am happy we have plenty of existing dehumidification as well, particularly in our basement. Temperature is also a part of air quality, and I am happy that our new mini splits will help us properly and efficiently heat two areas of our home that just didn’t get sufficient heat in the past. Installing mini splits is a great way to repair temperature control challenges without additional construction expense.

I feel like I am still beginning my journey regarding indoor air quality. I have studied this topic in theory, and I have made some changes that will improve our IAQ, but I have not yet measured the pollutants we can, and I finally feel ready to embark on this part of the project. As I have written in a piece on IAQ, I worry we’re starting to learn just how worrisome our indoor our should be, and some of what we can do about this, but most of us don’t know enough about what to do if we discover a particular problem, and maybe not everyone has the time or funds to make needed improvements. So there’s a chance I was too worried about what I might find out. I purchased indoor air quality monitoring equipment some time ago, but I haven’t yet tried it out. I am also interested in learning all I can about how “tight” or “leaky” our house is in terms of where we might be losing or gaining air, water vapor, and energy. So I am hoping to do some tests like infrared measuring and blower door tests to see what is coming in and out of our building, and how. I’d like to seal up any leaks for energy efficiency and moisture control purposes, while also making sure we have balanced and proper ventilation throughout. The ERVs are a big part of making sure we’re bringing in enough fresh air, and I look forward to learning the best plans or schedules for optimal operation. “Perfecting” IAQ will be my next phase, and I look forward to reporting in!

Have you embarked on an HVAC project you can share, small or large? What were your goals, and have they been met? What challenges did you face? Please feel welcome to comment, and also to submit your own upgrade report!

Progress! The unit on the left below is a VRF, or Variable Refrigerant Flow Heat Pump. Note that the variable in VRF relates to the increased levels of refrigerant flow gradation in these systems, resulting in greater control and comfort and energy efficiency. Where some systems might only have one motor speed, or two motor speeds, the added levels in VRF systems mean that the systems can better match energy use to actual conditions and demands, resulting in less energy use overall. The systems are also hihgly energy efficient and tend to run quieter.

On the right we have a heat pump compressor that only dlivers provides heat. It would need adjusting to provide both heating and cooling. When the zone served the the compressor on the right fails, everything is already set up for the next heat pump unit. We have the plan and we're ready, and it wil be a lot less work since we've prepared, but it could be years.

Our outdoor systems area was not very attractive before this project!

And then when it snowed, the equipment was too close to the ground.

When it snowed a lot, we had real problems.

We found this clever spot for one of the heat pumps, behind the house. I plan to make the base a little more attractive.

Additional/Related Information:

Residential Decarbonization – Influencing Consumer Demand Before Inflection/Decision Making Points is Key

Building Electrification: Why It Matters to Your Wallet, Health, Comfort, and the Environment

Electrification and Decarbonization Content Guide

Heat Pumps 101 - Comfort, Health, Savings, Energy Efficiency, and Lower Emissions

The Future of Natural Gas Cooking (Are "They" Coming to Take Your Stove Away?

Reducing the Natural Gas “Bridge,” for Human and Environmental Health

A Rate It Green Content Guide to Indoor Air Quality (IAQ)

Remote Hood Exhaust Fan Retrofit Delivers Significant Noise Reduction

- Filed Under: Heating, Ventilation, Air Conditioning (HVAC)

- Keywords : Energy Efficiency, HVAC, Heat Pumps, retrofits, Electrification, Heating, Renovations, Remodeling, VRF

- ( 4926 ) views

I am excited to work with the Members of the Rate It Green Community to host conversations, create connections, and generally share information and help green builders everywhere. Please feel welcome to reach out to me directly with suggestions for improving Rate It Green.

- ( 0 ) Ratings

- ( 104 ) Discussions

- ( 131 ) Group Posts

Reply/Leave a Comment (You must be logged in to leave a comment)

I should have added that we can keep our garbage cans in here as well, though we normally leave them out to be honest. The fence will also make it clear to steer clear of this area for snow plowing. (which our plow company has been great about in recent years.) We did make sure it would be spacious enough for the cans so they would not block the intake or exhaust for the compressors, but they do have to be tandem.

Connect with us!

Subscribe to our monthly newsletter:

Greenbuild Report Out, 2025 Nov 12, 2025

Greenbuild Report Out, 2025 Nov 12, 2025

Not a Member Yet? Register and Join the Community | Log in