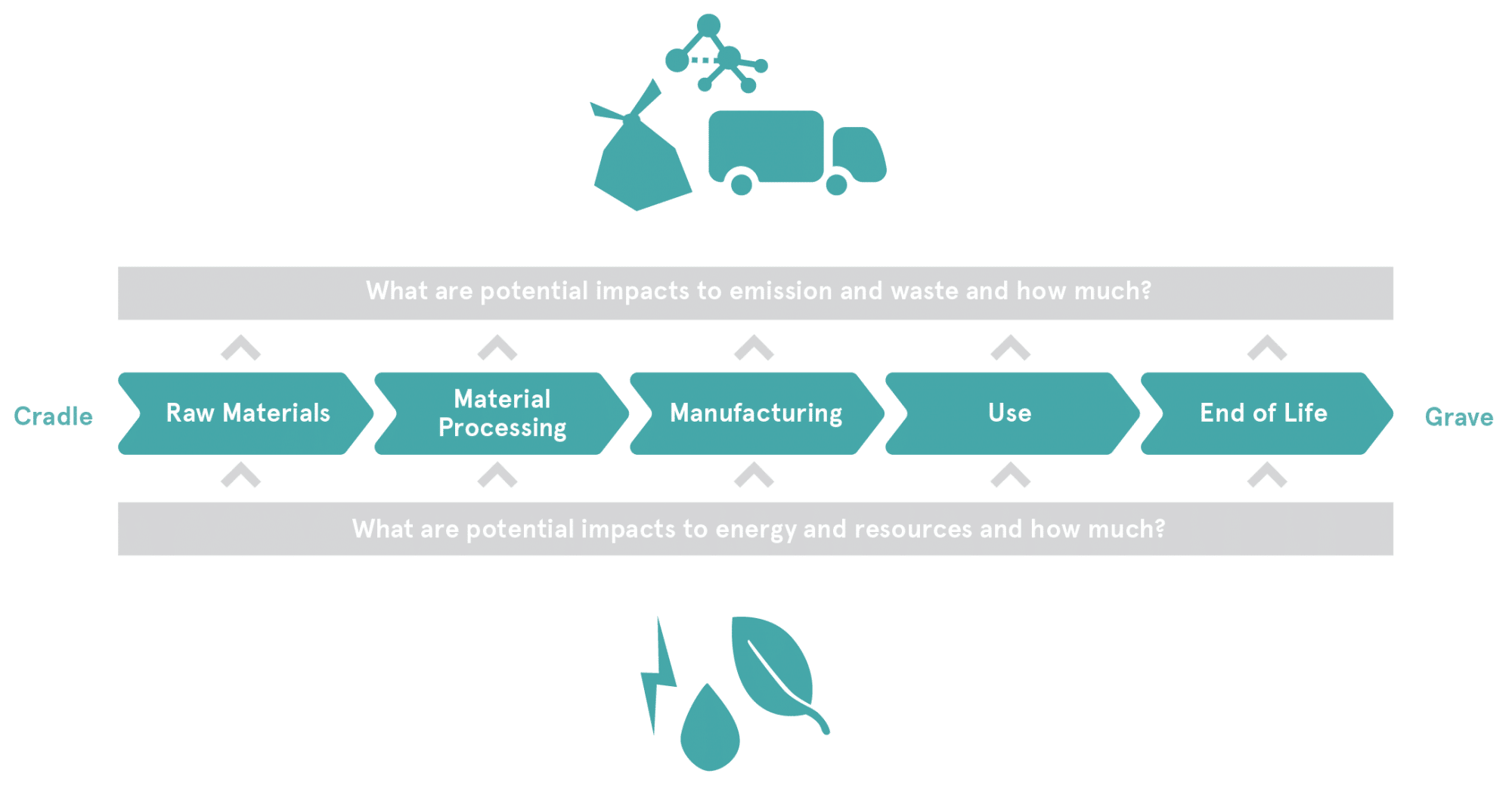

[Infographic: Pratt Center for Sustainable Design Strategies]

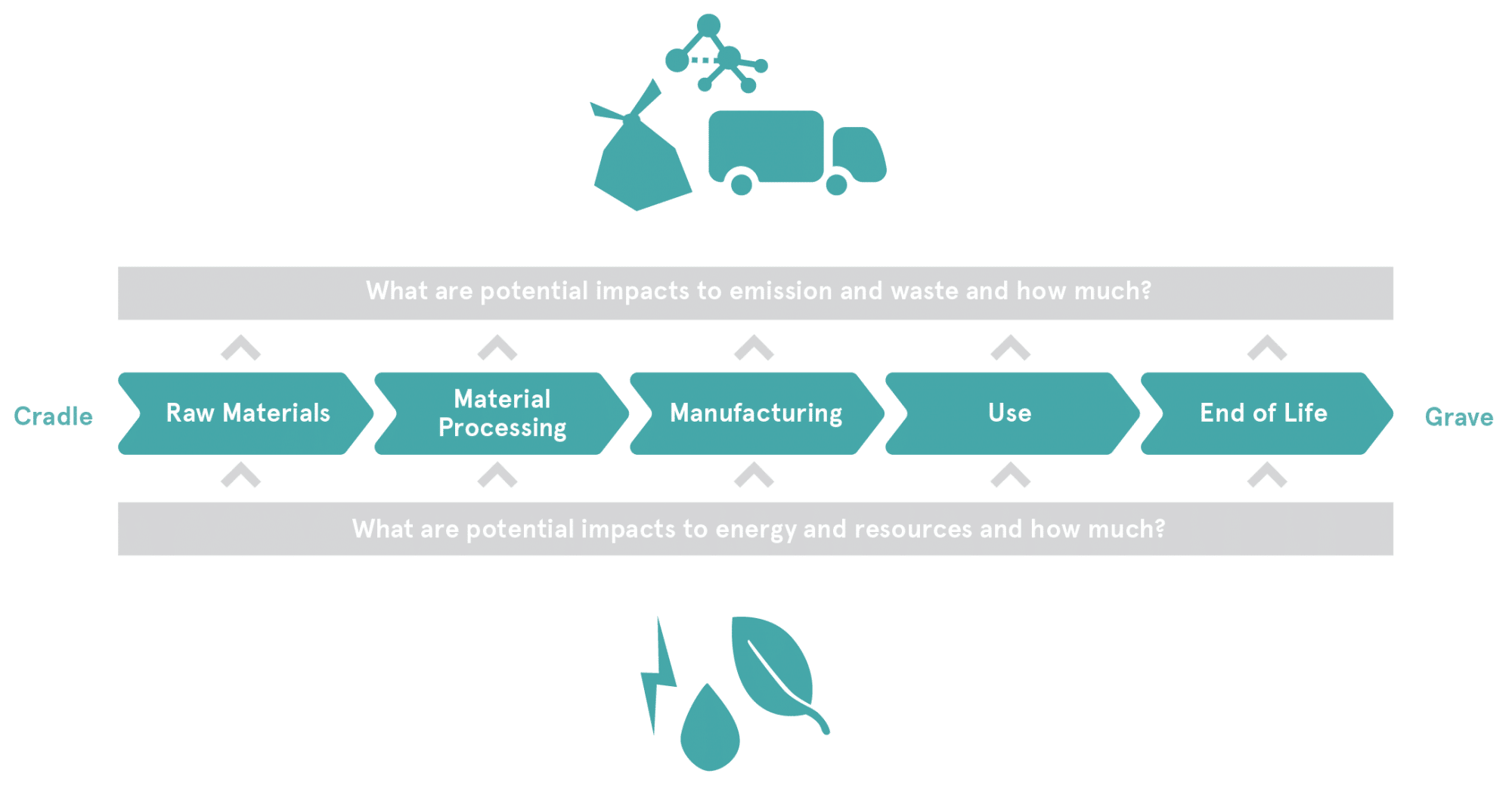

Sustainable materials management is a systematic method of using and reusing materials more productively over their full life cycles. Global consumption of materials has quickly risen over the last century. This has resulted in habitat destruction, biodiversity loss, and desertification, according to the EPA. Materials management is linked to an estimated 42% of total U.S. greenhouse gas emissions. This is why we need to adopt more sustainable ways to manage materials, for the sake of Earth.

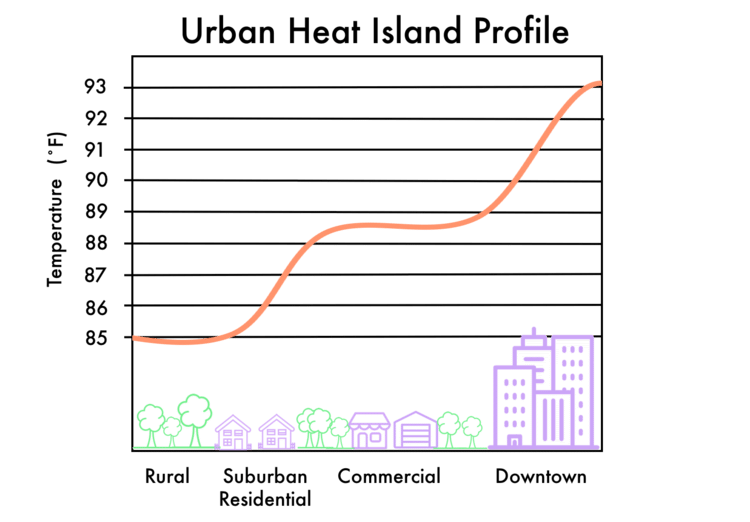

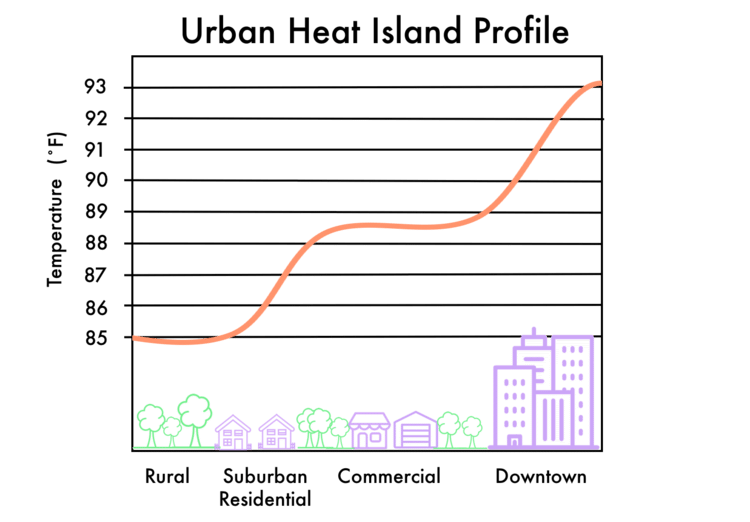

Smart Surfaces Coalition is promoting cost-effective sustainable material solutions, including cool roofs, permeable pavement, green roofs, and solar panels. More than 20 leading sustainability organizations, including the USGBC, formed the coalition. “The Smart Surfaces Coalition shows cities how to use advanced surface technologies to reduce heat and prevent flooding,” says Greg Kats, the coalition’s founder. “These solutions deliver enormous health and financial benefits, slowing global warming, enhancing quality of life, and saving taxpayers billions of dollars in energy costs.”

[Infographic: Smart Surfaces Coalition]

The USGBC reports that implementing smart surfaces will help U.S. cities cut excess heat days by half, save $700 billion, and create 270,000 jobs. Sustainable surfaces also reduce flooding and combat the urban heat island effect. The Smart Surfaces Coalition is already working with a dozen cities to provide training and resources to city officials. “Cities are increasingly at risk from severe summer heat,” Kats says. “This coalition will support adoption of smart surface technologies to save billions of dollars and cut greenhouse gases while making cities cooler, more resilient, healthier, and equitable.”

The societal and environmental benefits to implementing sustainable building materials in projects is undeniable. The most sustainable building materials have a lower environmental impact, like reused or recycled materials. Green building materials are durable and require less energy to manufacture. They don’t deplete scarce resources and can be locally sourced to reduce transportation emissions.

Let’s take a look at five sustainable building materials that are making waves in the industry.

Precast concrete panel provide stellar performance and efficiency. [Photo: Courtesy of Fabcon]

1. Precast Concrete

Concrete is one of the most common building materials in the world because of its durability and strength, but precast concrete is proving itself to be one of the most sustainable building materials. Precast concrete is produced in a controlled manufacturing plant and then transported to a site already reinforced and finished according to specification, which eliminates the need to cast concrete on-site and shortens the installation time. This makes precast concrete building less disruptive to the site environment, producing less construction debris, dust, noise, and pollution.

The materials used in precast concrete can be locally sourced, including the cement, the coarse and fine aggregates, and the steel, which reduces shipping waste and overall carbon footprint. Precast concrete units can be disassembled in an existing structure to be moved or reconfigured, and the concrete can be crushed and reused as aggregate. Fabcon Precast, a leader in the precast concrete industry, uses a combination of concrete and EPS foam that maximizes the foam in the concrete piece—increasing insulation capabilities.

Tiny Houses, Big Deal May 10, 2019

Tiny Houses, Big Deal May 10, 2019

Not a Member Yet? Register and Join the Community | Log in