Solar Fresh Air Heating Systems for New Builds or Retrofit Industrial, Commercial, Institutional and Multi-Residential Projects

Building-integrated, solar fresh air heating systems offer the best return on investment of any renewable technology for new or building retrofit projects in the industrial, commercial, institutional or multi-residential markets.

According to ASHRAE Standard 55, the temperature of the air in a building should range from 20 to 240 C during the winter and transpired solar air collectors serve to pre-heat ventilation air without using other fuels thereby reducing energy demand. Thermal heating of non-residential buildings accounts for over 30% of the total energy consumption in the United States according to the Centre for Climate and Energy Solutions. Typically, eighty-five percent of this energy is derived from non-renewable, fossil fuels yet there are several ways to use energy more efficiently, and produce energy using renewable sources with products that integrate aesthetically, seamlessly and cost effectively within a buildings’ architecture.

Unglazed, transpired solar air heating systems have high operating efficiencies (70% to 89%), and utilize existing building mechanical systems in order to function. In 2011, the US Department of Energy demonstrated that “…unglazed, transpired solar ventilation preheating systems deliver fresh air up to 400 F above ambient temperatures thereby reducing or eliminating the need for conventional ventilation air preheating systems. Such systems are intentionally designed for cold climates, demonstrating an incremental payback history of between two and eight years with best installations located in areas with cold weather but significant sunshine typical of the northern states. Given their relatively quick payback, ease of integration on new or retrofit applications and the aesthetically pleasing designs, building owners planning façade renovations should evaluate whether a transpired solar air heating systems is a viable option…”

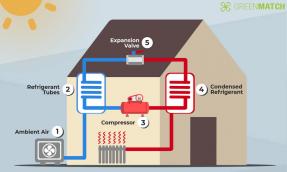

How the transpired solar collector systems work.

Using a combination of vertical and horizontal metal framing to create an air cavity, a dark, perforated, metal cladding (absorber) is installed on a south-facing wall over the building’s ventilation system air intake. Both diffuse and direct solar radiation strike the absorber and as the air passes through the perforations the sunlight is converted into heat.

Outdoor air is drawn through the perforated exterior cladding (absorber) at flow rates of 4 – 7 CFM/ft2 of collector area and into the void cavity between the cladding and the building’s exterior structural wall. Higher air flow rates are suggested for high-rise applications to mitigate the impact of heat loss due to ambient wind on the absorber. As the air travels through the space behind the absorber, it is heated up to 250C over ambient temperatures and the warmed air is then drawn into the building as fresh ventilation air.

Key Features and Benefits

Using the buildings HVAC system to function, solar air heating systems have virtually no operating cost. Conservatively, façade mounted transpired solar collectors will yield energy savings of 1.5 - 3.0 GJ/m2 of installed collector area on an annual basis delivering this energy at an incremental cost of $0.03 – 0.07/kWh based on a twenty five year life cycle cost basis.

Transpired solar air heating systems require no maintenance. Studies have shown that static electricity leads dust particles to attach themselves to the exterior surface of the absorber around each perforation which is then naturally removed, washed away, with rainfall. As a indirect side benefit, air is naturally filtered with further studies indicating a 50% reduction in airborne particulate thus reducing maintenance costs and improving indoor air quality.

While black is the colour that provides the best energy output, any colour may be used and the standard coatings used to produce the perforated absorber on the collector carry forty year warranties on their finish.

System Design Considerations

Solar collectors operate best when sunlight strikes the absorber directly at a right angle. To utilize the most powerful sunlight available in the day solar collectors used in the Northern Hemisphere should be oriented true, not magnetic, south for optimum year round performance. East and west facing walls are also suitable; however their cost benefit would be compromised.

The silicone modified polyester coatings used on building-integrated, perforated or transpired galvanized steel absorbers come in a variety of colours for aesthetic purposes, each with varying solar absorption and emissivity properties depending on their colour. Ideally coatings with high absorptivity and low emissivity are best suited and at this time black is still the most beneficial colour for any solar thermal collector having a solar absorptance of 0.95 with an emissivity of 0.88, while Bright White for example has a an absorptance of just 0.33 some 65% less effective at attracting the sun's rays.

The ambient wind exposed to a building-integrated absorber can have a profound impact on the energy output of the solar air heating system. At collector flow rates of 8 CFM/ft2 the average transpired solar collector efficiency drops from 74% to 59% when the ambient wind speed increases from 1.5 MPH to just 7 MPH over the absorber. The reduction is greater still at minimal collector flow rates of 4 CFM/ft2 as overall average efficiency drops from 57% to 40% when the ambient wind speed increases from 1.5 MPH to just 7 MPH over the absorber. Therefore, to maximize system efficiency and increase return on investment designers should therefore size collectors using the higher flow rate of 7 – 8 CFM/ft2 of collector area particularly in high-rise building applications where ambient wind increases with the height of the building.

The transformation of sunlight to heat is instantaneous. When operating properly the perforated absorber will feel cold to the touch, even on a sunny, cold winter day. No heat should remain on the absorber. While colour is an important consideration, studies and field results demonstrate that the absorber material, be it galvanized steel, aluminum or a polycarbonate will have a very marginal impact on the systems’ actual performance.

The performance of a solar air heating system may be readily predicted using prefeasibility simulation software such as RETScreen™ developed by Natural Resources Canada which uses NASA Surface Meteorology and Solar Energy Data Set for its weather data including solar radiation to model solar air heating system performance for any location in the world.

The energy retrofit at LBJ Apartments in Boston, MA is an example of one such solar air heating system retrofit and serves as “a showcase for clean, renewable technologies.” said Greg Russ, CHA's Executive Director. "Matrix Energy’s solar heating system is part of the technology package that will contribute to our effort to reduce our environmental footprint, by adding renewable energy technology that pays for itself, improves the performance of the building and introduces new energy conservation techniques to the region." Says Paul Hewins Executive Vice President and General Manager of Skanska USA’s New England Operations, “Matrix Energy’s SRCC certified, solar air heating system is a key element in achieving the energy performance objectives for this retrofit.”

The LBJ project is on track for a 50% reduction in energy use at the property, as well onsite renewable energy generation exceeding 10% of the projected post retrofit energy needs. The solar air heating system custom-designed for LBJ Apartments by Matrix Energy will produce approximately 300 million BTUs of solar heating during each heating season, cutting annual natural gas consumption by more than 100,000 kWh – more than $5,000 in savings - while providing an annual 18 tonne reduction in CO2 emissions. In addition to being entirely maintenance free, unglazed transpired solar air collectors are recognized for their air filtration ability with studies (Enermodal, February 2000) showing a 50% reduction in particulate matter entering the HVAC system resulting from the static build-up of dirt particles around the perforations that are cleaned naturally by rainfall.

- Filed Under: Heating, Ventilation, Air Conditioning (HVAC)

- Keywords : Solar Fresh Air Heating Systems

- ( 17316 ) views

Since 1990 Matrix Energy has supplied over 41,000 m2 of solar air heating collector area spanning hundreds of commercial, industrial, institutional and multi-residential installations across Canada, the United States and Europe. (Please see http://www.matrixairheating.com/matrixair-projects.html for a brief assortment of our installed portfolio.)

- ( 0 ) Ratings

- ( 0 ) Discussions

- ( 0 ) Group Posts

Reply/Leave a Comment (You must be logged in to leave a comment)

Connect with us!

Subscribe to our monthly newsletter:

.JPG)

Not a Member Yet? Register and Join the Community | Log in